Our Services

Our Services

Solutions to all Industrial and Mining needs of Statutory, Safety, Environment and legal formalities relating to the concerned authorities.

Inspection and Testing for Certification of Machines, Lifting Tools and Lifting Tackles on par with Factories Act 1948, The Karnataka Factories Rules 1969.

Inspection,Testing & Certification

Lift,Hoists, Lifting Machine, Lifting Tools & Tackles:

Inspection and testing for certification of Lifts, Lifting Machines, Lifting Tools and Lifting Tackles. The detailed checklists and testing facilities allow us to provide a thorough inspection of EOT cranes, Gantry Cranes, Hydras, Cherry-pickers, Hoists, Chain Pulley Blocks, Winches, Goods Lifts, and Lifting Tackles/gear.

Electrical Chain Hoist

Lift

EOT Crane

Lifting Tools & Tackles

Visual Inspectionof wire ropes, hook and hook latch and Testing [Load test]

Display of SWL, ID No., Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions duringinspection and test results

Pressure Vessel and Pressure Plants

Visual Inspection, Testing, Hydrostatic/Pressure test, Ultrasonic Thickness Testing of Pressure Vessel for Certification as per norms and procedures.

Pressure Vesssel

Pressure Vesssel

Visual inspection of safety relief valve, pressure gauge, Pressure Switch and Drain cock

Ultrasonic Thickness Test

Hydrostatic Test / Pressure Test

Display of Max. W. Pr, Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions duringinspection and test results

Centrifugal Machines

Inspection and Testing for Certification of Centrifugal Machines as per the standard norms.

Centrifugal Machine

Visual Inspection of locks, inter locks, sensors & speed

Display of Capacity, speed, Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions during inspection and test results

Power Press

Inspection and Testing for Certification of Power Press as per as per the standard norms.

Power Press

Visual Inspection of punch, die, die set, clutch, brakes, oil leakage & bar screen sensors

Display of capacity, Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions during inspection and test results

Shot Blasting Machine

Inspection and Testing for certification of Shot Blasting Machine as per standard norms

Shot Blasting Machine

Visual inspection of Nozzles and blast cabinets [generated dust]

Display of air pressure, Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions during inspection and test results

Dust Extraction System

Inspection and Testing for certification of Dust Extraction System as per standard norms.

Visual inspection of ventilation systems, pressure rating, filter and dust collection bag

Display of pressure rating, Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions during inspection and test results

Ovens & Dryers

Inspection and Testing for Certification of Ovens & Dryers as per standard norms.

Dryers & Ovens

Visual inspection of Temperature gauge, Air flow rate, Temperature cut-off sensor

Display of Temperature, Air Flow, Inspection Date & Due Date

Documentation and reports of inspection

Corrective actions during inspection and test results

Ventilation System

Inspection and Testing for Certification of ventilation systems as per standard norms.

Ventilation System

Visual inspection of air flow discharge, pressure rating

Display of inspection date & due date

Documentation and reports of inspection

Corrective actions during inspection and test results

Full Body Harness

Inspection and Testing for Certification of Full Body Harnessas per the standardnorms.

Full Body Harness

Visual inspection of ropes, belts and locking clips

Display of maximum Safe Working Load [Capacity]

Documentation and reports of inspection

Corrective actions during inspection and test results

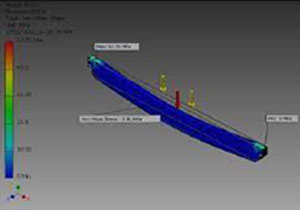

Remnant Life Analysis

Remnant Life Analysisof pressure vessels, receivers, storage tanks, machines, equipment’s, chimneys, boilers, specific parts using advanced tools and techniques to predict the life assessment using structural, low cycle and high cycle fatigue.

Visual Inspection and Collection of technical details

Modelling

Analysis

Documentation and reports

Corrective measures and recommendations

Environmental Services

Preparation of documents to obtain NOC, environmental clearance from MoEF

Air Quality

Water Quality

Sound/Noise Level Monitoring

Illumination Survey

Monitoring of air quality and water quality

Collection of details of sound/noise

Level of Illumination

Meteorological details like temperature, wind velocity, wind speed and etc.

Documentation and reports

Corrective actions during monitoring and test results

On Site Emergency Plan (OSEP)

Procedure which is designed to control emergency situations so as to provide safety and security to the stakeholders until the business continuity or normal business plan resumes.

Collection of technical details

Work out of emergency exit plan

Documentation and reports

Corrective actions plan

Stability Analysis

A Stability Analysis is an overall health and performance check-up of a building. Old buildings/structures have reduced strength in due course of time and such structures in continual may end anger the lives of the occupants, machineries and buildings. Stability analysis is performed for existing buildings to improve the performance of structures to restore desired functions.

Collection of technical details to assess the condition of building

To identify critical prone areas

To comply with statutory regulations.

Evaluation by software

To recommend corrective measures

Safety Audit and Management

Implementation

Preparation of System Manual

Standard Operating Procedure (SOP)

Checklists

Safety work permits

Workplace Safety

Expansion, Modification and Work Permit systems

Safety Training

SAC Approval (Site Appraisal Committee)

Preparation of required documents & submitting to Department as per The Factories Act 1948, First schedule (section 2 (c b)), and Chapter IV – A, section 41 A.

Preparation of document for getting cosmetic license from drug control department

Preparation of required documents & submitting to Dept. of Drug Control & getting approval for the same.

Preparation of mining plan & statutory plan

Preparation of Mining plan/Scheme of mining as per the norms of Indian Bureau of Mines & Statutory Plans. Getting the seal of approval for the same.

Factory Layout

The Building plan of factory, Machinery layout plan for new and existing factories & getting the approval from the Dept. of Factories, Boilers, Industrial safety and Health, Govt. of Karnataka.